Explosion Vent Manufacturers in India - Expro Technologies

Expro Technologies is a leading explosion vent manufacturers in India, suppliers, traders, dealers and exporters in India. We are providing the high quality of explosion vent or also known as explosion vent panel which is a safety device and designed to protect the equipment and buildings from excessive pressure that is caused by providing a controlled pressure release. These panels are designed to burst or open at a predetermined pressure, allowing the excess pressure and flame front to exit to a safe area. Explosion vent panels are a passive protection system that opens when the inside of a dust collector or other vessel reaches a predetermined pressure.

Explosion Vent Traders, Dealers and Exporters in India

Working Principle of an Explosion Vent

An Explosion Vent is a safety device that relieves excessive pressure during an explosion and prevents from any kind of equipment damage.

How It Works:

- Normal Operation: Stays sealed under regular conditions.

- Pressure Build-Up: Rapid pressure increases from an explosion.

- Vent Activation: The burst panel automatically opens when pressure exceeds the limit.

- Pressure & Flame Release: Directs explosion energy safely.

- Reset or Replacement: Must be replaced after activation.

Advanced Features of Explosion Vent:

- Smart Sensors: The use of new smart sensors in these explosion vent can automatically detect the pressure changes in real time basis.

- Flameless Venting: This explosion vent has frameless venting and it contains flames for indoor safety.

- AI Monitoring: The use of new AI monitoring in these machines can automatically detect failure points for preventive action.

Explosion vents are crucial in industries handling combustible dust, gases, and volatile materials. These materials give safe pressure relief.

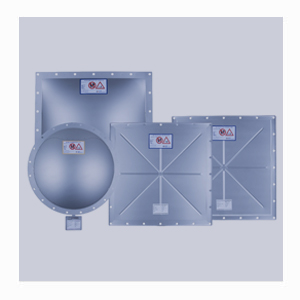

Types of Explosion Vent

As a former explosion vent manufacturers and suppliers in India, we are providing the highly demanding and strong quality of explosion vent such as:Types of Explosion Vent

As a former explosion vent manufacturers and suppliers in India, we are providing the highly demanding and strong quality of explosion vent such as:

- SS Explosion Vent (Stainless Steel Explosion Vent): These are made from high-quality stainless steeland have a robust working mechanism, making them durable for safety devices. Designed to release excessive pressure from industrial explosions, they are ideal for high-temperature and corrosive environments. The multi-layered construction improves burst control and pressure relief efficiency.

- Flameless Explosion Vent: With a frameless design, it provides a safe way to vent explosions without flames escaping, making them ideal for indoor applications where traditional vents are a fire hazard. It uses a metal mesh or flame arrestor to extinguish flames, preventing secondary explosions in confined spaces. Suitable for dust collectors, silos, and enclosed process vessels.

- Domed Explosion Vent: These newly shaped dome explosion vents are specifically designed for applications with fluctuating pressure and vacuum conditions. They offer reliable explosion relief while maintaining system structural integrity. Their curved design improves durability under pressure cycling and are suitable for applications with varying pressure loads. Available in stainless steel and composite materials.

- Graphite Explosion Vent: Made from pure graphite, these new vents are designed for high-temperature environments where conventional metal vents may fail due to thermal expansion. They are used in highly reactive environments and are lightweight and durable compared to other types, making them suitable for various industrial applications.

Technical Specification of Explosion Vent

For more clarification, we have mentioned below a technical sheet table of explosion vent such as:

| SS Explosion Vent | Flameless Explosion Vent | Domed Explosion Vent | Graphite Explosion Vent | |

|---|---|---|---|---|

| Material | Stainless Steel (304, 316) | SS + Flame Arrestor Mesh | SS, Aluminum | Graphite Composite |

| Burst Pressure | 0.1 - 2 bar | 0.2 - 1.5 bar | 0.05 - 1.0 bar | 0.2 - 3.0 bar |

| Temperature Limit | Up to 600°C | Up to 300°C | Up to 500°C | Up to 800°C |

| Application | Silos, Dust Collectors | Indoor Industrial Use | High-Pressure Systems | Chemical Reactors |

| Explosion Protection | Passive Venting | Flame Suppression | Shock Resistance | Chemical & Heat Resistant |

| Compliance | NFPA 68, ATEX, ISO 4126 | NFPA 68, ATEX, EN 14491 | NFPA 68, VDI 3673 | NFPA 69, ATEX |

| Burst Pressure Range | 0.1 - 2 bar | 0.2 - 1.5 bar | 0.05 - 1.0 bar | 0.2 - 3.0 bar |

| Temperature Resistance | Up to 600°C | Up to 300°C | Up to 500°C | Up to 800°C |

| Vent Efficiency (%) | 90 - 98% | 85 - 95% | 88 - 97% | 92 - 99% |

| Installation Orientation | Horizontal / Vertical | Horizontal / Vertical | Vertical / Angular | Horizontal / Vertical |

Features of Explosion Vent

One of the leading explosion vent manufacturers and traders in India, these all types of explosion vent are made with new latest features such as;

- Passive & Flameless Protection: Compared to traditional explosion vents, these modern types offer passive and frameless protection, releasing pressure through venting without creating secondary hazards like flames or shockwaves in the same environment.

- Multi-Layer Construction: Unlike older vents made from single-sheet metal with limited lifespan and resistance, these new modern vents utilize strong quality materials with multi-layer construction, often using composite materials with multiple proactive layers to significantly improve durability and functionality.

- Zero Maintenance Design: While most explosion vents are single-use devices requiring replacement after activation, these explosion vents are designed to eliminate the need for routine servicing, making them more cost-effective and maintenance-free. Unlike mechanical relief systems, they do not require lubrication, calibration, or regular adjustments.

- ATEX & NFPA Compliance: Our all types of new explosion vent panels are certified with strict international safety standards, ensuring higher reliability in hazardous areas. They comply with ATEX (Europe - Directive 2014/34/EU), NFPA 68 (USA - Standard on Explosion Protection by Deflagration Venting), and ISO 4126 (Global - Pressure Relief Devices Standard), guaranteeing high safety standards and regulatory compliance.

Applications of Explosion Vent

These all types of explosion vent panel are majorly used in multiple types of industrial sectors such as:

- Grain silos, dust collectors, and bulk storage bins

- Pharmaceutical processing, reactors, and chemical drying units

- Petrochemical plants, refineries, and gas storage facilities

- Battery energy storage, EV charging stations, power grids

- Food processing, sugar mills, and flour production plants

- Oil and gas refining, pipelines, and offshore rigs

- Hydrogen fuel cells, electrolyzers, and renewable energy systems

- Industrial dryers, furnaces, kilns, and high-heat applications

- Coal-fired power plants, biomass energy, and boiler systems

- Metal processing, woodworking, and combustible dust environments

Frequently Asked Questions (FAQs)

It is a high-strength vent made from 304 or 316 stainless steel, ideal for corrosive and high-pressure environments.

It integrates a flame arrestor that absorbs heat, allowing pressure relief while preventing flames from escaping.

The curved design improves structural integrity, making it suitable for high-vacuum and pulsating pressure applications.

It features multi-layer construction with metal and polymer, offering superior chemical resistance and extended lifespan.

As a dominant explosion vent manufacturers in India, suppliers, traders, dealers and exporters in India, we as Expro Technologies are providing the high quality of explosion vent. These explosion vents are used in the hazardous and sensitive types of areas for keeping the environment safe. We have used pure form of materials inside these explosion vent for maintaining and resisting thermal temperature and any kind of external threats. Due to these all types of qualities inside, these are used in many types of large industrial sectors. Contact us today for more information!