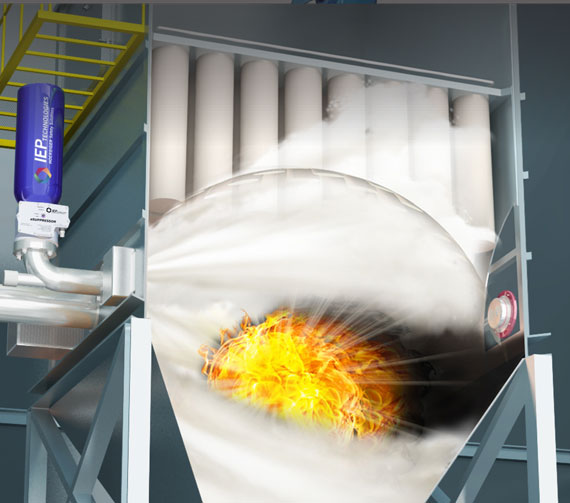

Explosion Suppression System

Explosion Suppression System detects the initial phase of an explosion inside the device and subsequently suppresses the explosion of combustible dust in industrial technologies. The reaction time of the control unit is in milliseconds. This system effectively suppresses the explosion and reduces the explosion pressure inside the device below the limit of its pressure resistance, thus preventing its destruction. This system eliminates damage to technology, but above all, it protects human health and lives. Protects against the consequences of explosion in filters and filtration units, industrial vacuum cleaners, silos, mills, elevators, dryers, cyclones, conveyors, powder containers, mixers, crushers, and other industrial equipment.

Features

Quick system response

Highly efficient technology

Application indoor and outdoor

Suitable for toxic and otherwise hazardous materials

Independent archiving of data from the detector

Possibility of adjustment according to customer requirements

Enquire Now

eSUPPRESSOR™

The IEP Technologies eSUPPRESSOR™ is a high-rate discharge suppressor used for explosion suppression and isolation systems. Its electro-mechanical operation is unique to the industry, as no pyrotechnic devices are required for activation. The eSUPPRESSOR has standard features that include pressure monitoring, lock outtag out capability and LED indication of device status. A key benefit is that all the safety functions are fully monitored, which is not possible for any device employing pyrotechnic actuators. The eSUPPRESSOR design and manufacture has SIL2 third party certification.

EHRD II Suppressor

The EHRD II suppressor is designed for installation on all types of vessels, ducts and pipes for dusts, gases and hybrid mixtures. The suppressor valve is closed with a domed disc and sealing ring and then pressurized with nitrogen.